What is extrusion in 3D printing?

What is extrusion in 3D printing?

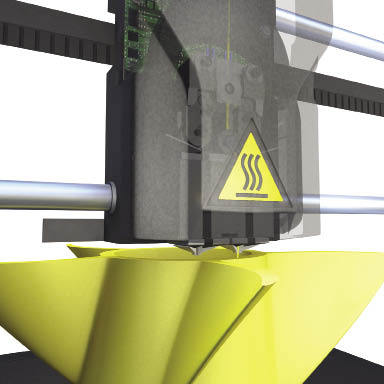

According to the ASTM International standards organization, extrusion is the official name given to a specific 3D printing process where material is selectively dispensed through a nozzle or orifice. Extrusion is more commonly known as Fused Deposition Modeling (FDM)®, a registered trademark by Stratasys Ltd, or Fused Filament Fabrication (FFF), a non-trademarked term.

Ensuring that the material and the nozzle move together is challenging, as both are constantly changing. Lower cost extrusion systems often use stepmotors that drive belts to move the plotter system, but the tradeoff is accuracy and speed. The more expensive extrusion systems use servo drives and lead screws, which deliver the needed accuracy for more precisely built parts as shown in the Stratasys example here.

Extrusion is the most common and probably the simplest 3D printing technique. It can be used in almost every environment. The main printing material is a plastic filament. The filament is heated, melting in the printing head of the 3D printer.

Extrusion is an “additive” technology commonly used for modeling, prototyping, and production applications. It creates an object by laying down material in layers; a plastic filament or metal wire is unwound from a coil and supplies material to produce a part. The technology was developed by S. Scott Crump in the late 1980s and was commercialized in 1990.