Polyethylene Terephthalate Glycol (PETG) – what is it?!

Polyethylene Terephthalate Glycol (PETG) – what is it?!

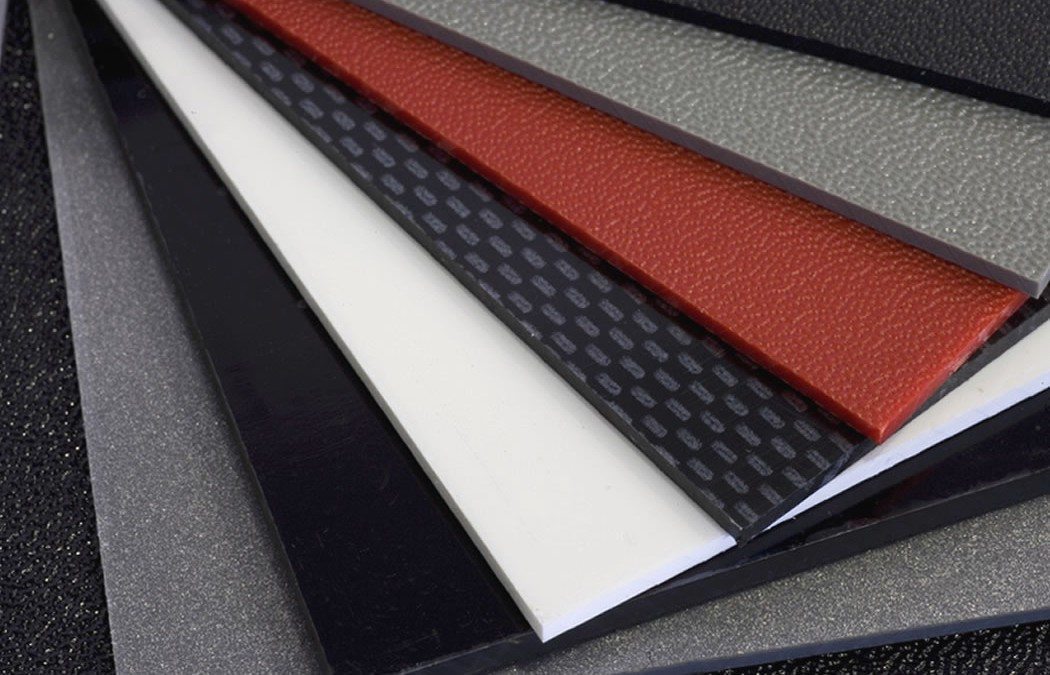

Polyethylene Terephthalate Glycol (PETG) is a water clear material and designed to be very ‘easy to use’ in a range of applications. It’s a thermoplastic polymer created through the copolymerisation of PET and ethylene glycol.

Properties

Being a copolymer, Polyethylene Terephthalate Glycol’s chemical formula is (C10H8O4)n and its properties include being transparent with a high gloss surface. It’s got a high impact resistance which is similar to polycarbonate and it’s also incredibly ductile. PETG has an excellent chemical resistance, is easily thermoformable and is also capable of reducing sound transmissions while also being sterile and recyclable.

Polyethylene Terephthalate Glycol fabricates well throughout a number of different processes including cutting, drilling, bending, routing and polishing. It’s also possible to silk screen PETG using various inks. It also bonds well with solvents or adhesives. Due to its low forming temperature, PETG can be easily vacuum or pressure-formed and bent by heat. There’s also no need for predrying. Its density is 1.27g/cm3 and its maximum service temperature is about 78˚C meaning that it shouldn’t be continuously exposed to temperatures above 65/70˚C. PET is usually more fire resistant then PETG, having an ISO test flammability rating of H-B which is relatively low.

Overall PETG is a high-impact material but it’s not suitable for use in outdoor applications, although UV resistant stabilisers can be added to it. The UV rays in solar radiation will degrade most plastics in time, but this exposure depends on the temperature humidity, angle of the sheet in respect to the solar radiation and its intensity. Degradation can be seen by the plastic becoming more yellow and there will also be a decrease in light transmission and its mechanical properties. PETG is also vulnerable to scratching, so avoid placing it in high contact environments.

Purposes

Polyethylene Terephthalate Glycol can be used in a variety of applications including for medical and food purposes, electronic devices, covers and even medical braces. PETG is often used in the sign making industry where it can create purchase or graphic displays and display cases.

Printing grade PETG provides excellent printability, laminating characteristics and flexural strength. It’s suitable for a range of applications and is now being used to make credit or gift cards because it’s a more environmentally friendly alternative to rigid PVC.

Due to its impact resistance properties, PETG is also being used in thermoforming applications which require deep draws and complex shapes.